T: +86-577-86867777

E: info@jhenten.com

E: info@jhenten.com

No.808 Haitong Road, Binhai Development Zone,Wenzhou Economic and Technological Development Zone,Zhejiang,China

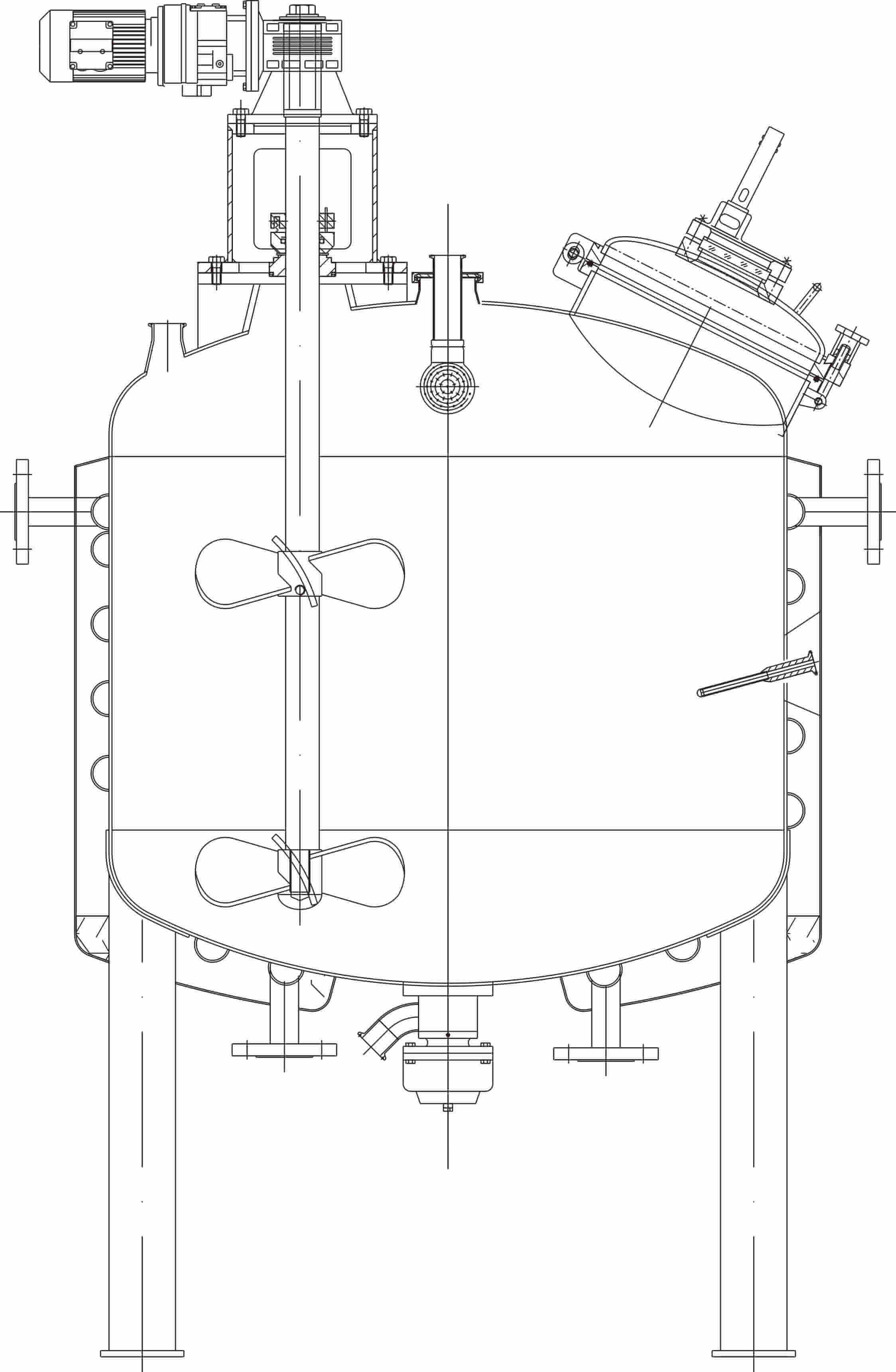

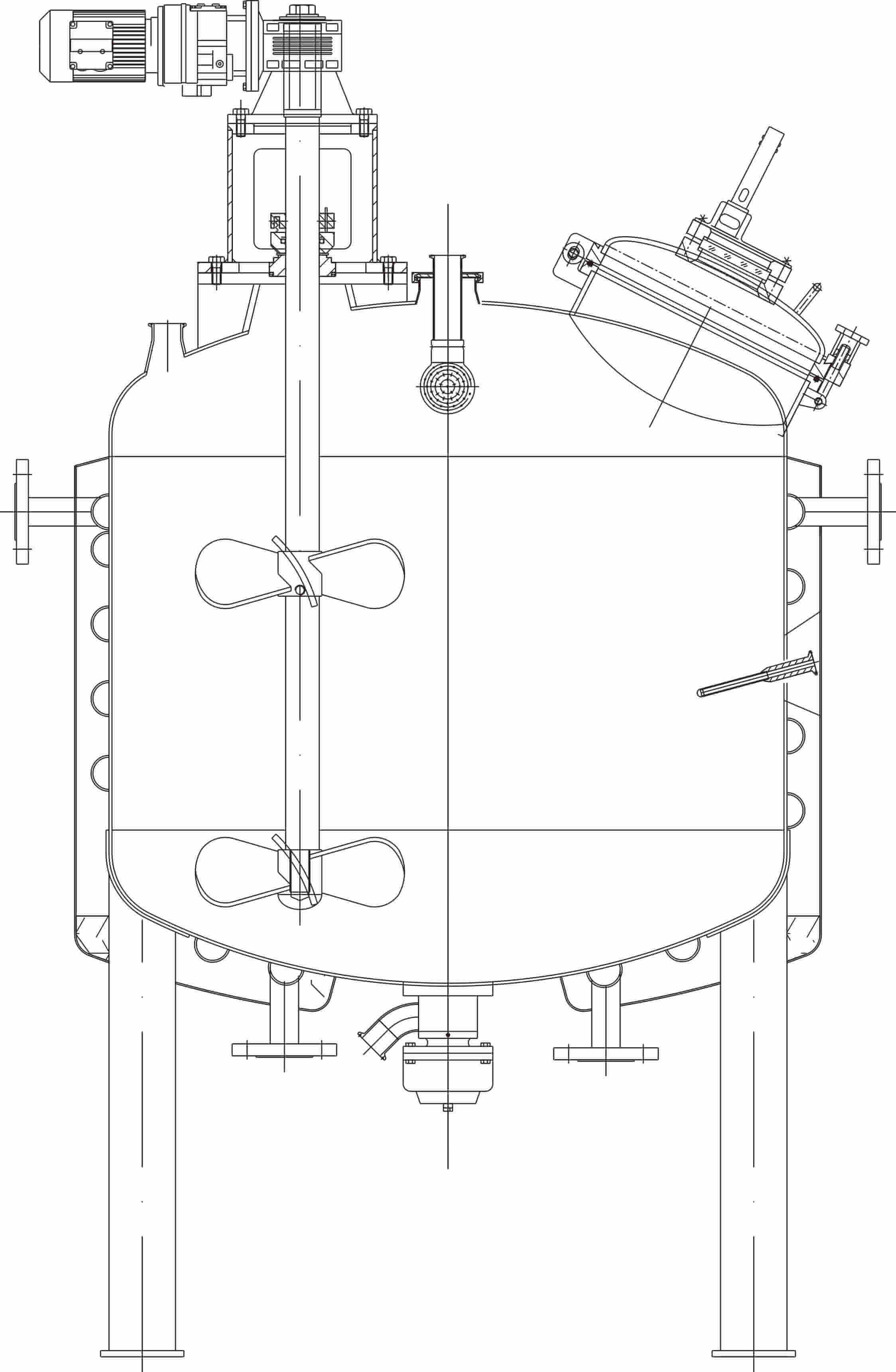

The JTRPG Mixing Tank strictly follows the requirements of Article 31 and 32 of the GMP General Principles of Good Manufacturing Practice of Medical Products (revised in 2010), and is designed, manufactured and inspected in accordance with Pressure Vessels (GB150-2011) and Steel Welded Normal Pressure Vessels (with Standard Interpretation) (NB/T47003.1-).

Mixing Tank features vertical circular tanks with standard oval and torispherical heads at the top and bottom. The transition section in the tank is designed with a circular arc transition, ensuring there are no dead corners and making it easy to clean. The tank can be single-layered, double-layered (cylinder and bottom have jacket and insulation), or equipped with a jacket (cylinder and bottom have jacket and insulation). Additionally, it can be equipped with a mechanical stirring system based on customers' preferences.

●Capacity: Ranging from 100 liters to 10000 liters, with various specifications available. Customized designs and manufacturing are also offered to meet customers' specific needs.

● The tanks are equipped with Tri-clamp connections, and the inner layer is made of either 304 or 316L stainless steel.

● To cater to different production and processing requirements, the tanks can be designed with features such as low heating, cooling, high-speed mixing systems, sealing pressure systems, vacuum systems, and measuring systems.

● Depending on the materials being mixed and the desired mixing effect, the impeller structure can be customized to be turbine type, paddle type, anchor type, frame type, screw impeller, and more.

Structure

Jhenten concentrated/dilute mixing tank (blending tank) using a vertical round tank, the tank can be equipped with jackets, coils, insulation (can be heated, cooled, heat preservation); stainless steel material is made of 316L or 304.

Design Parameter

Design pressure | Cylinder:-0.1MPa~1MPa,jacket:(ATM~0.5MPa) |

Design Temperature | According to customers’ requirement(0℃~200℃) |

Material

Inner shell | SS304, SS316L, Duplex SS, Titanium, Hastelloy |

Jacket | SS304, SS316L, Duplex SS, Titanium, Hastelloy |

Insulation | Rock wool or PU |

Leg | SS304 |

Connection

In-outlet | Tri-clamp, Flange,Thread |

Surface Finish

Finish Type | Mechanical/electrolytic polishing, sand blasting, pickling |

Polishing precision | Inner surface Ra≤0.4μm, |

Normal Model And Main Technical Parameters

Parameters | Model | JTRPG—100 | JTRPG—300 | JTRPG—600 | JTRPG—1000 | JTRPG—2000 |

Effective volume:L | 100 | 300 | 600 | 600 | 2000 | |

Tank | Diameter:mm | Φ500 | Φ800 | Φ900 | Φ1100 | Φ1300 |

Height:mm | 500 | 700 | 900 | 1000 | 1500 | |

Agitator | Power:kW | 0.37 | 0.75 | 1.1 | 1.5 | 2.2 |

RPM:r/min | 36~53(Special open turbine impellers)/200(propeller)(Can adjust the design according to the customer's | |||||

The above-mentioned data is the standard, it can customize according to customer's requirements. | ||||||

The JTRPG Mixing Tank strictly follows the requirements of Article 31 and 32 of the GMP General Principles of Good Manufacturing Practice of Medical Products (revised in 2010), and is designed, manufactured and inspected in accordance with Pressure Vessels (GB150-2011) and Steel Welded Normal Pressure Vessels (with Standard Interpretation) (NB/T47003.1-).

Mixing Tank features vertical circular tanks with standard oval and torispherical heads at the top and bottom. The transition section in the tank is designed with a circular arc transition, ensuring there are no dead corners and making it easy to clean. The tank can be single-layered, double-layered (cylinder and bottom have jacket and insulation), or equipped with a jacket (cylinder and bottom have jacket and insulation). Additionally, it can be equipped with a mechanical stirring system based on customers' preferences.

●Capacity: Ranging from 100 liters to 10000 liters, with various specifications available. Customized designs and manufacturing are also offered to meet customers' specific needs.

● The tanks are equipped with Tri-clamp connections, and the inner layer is made of either 304 or 316L stainless steel.

● To cater to different production and processing requirements, the tanks can be designed with features such as low heating, cooling, high-speed mixing systems, sealing pressure systems, vacuum systems, and measuring systems.

● Depending on the materials being mixed and the desired mixing effect, the impeller structure can be customized to be turbine type, paddle type, anchor type, frame type, screw impeller, and more.

Structure

Jhenten concentrated/dilute mixing tank (blending tank) using a vertical round tank, the tank can be equipped with jackets, coils, insulation (can be heated, cooled, heat preservation); stainless steel material is made of 316L or 304.

Design Parameter

Design pressure | Cylinder:-0.1MPa~1MPa,jacket:(ATM~0.5MPa) |

Design Temperature | According to customers’ requirement(0℃~200℃) |

Material

Inner shell | SS304, SS316L, Duplex SS, Titanium, Hastelloy |

Jacket | SS304, SS316L, Duplex SS, Titanium, Hastelloy |

Insulation | Rock wool or PU |

Leg | SS304 |

Connection

In-outlet | Tri-clamp, Flange,Thread |

Surface Finish

Finish Type | Mechanical/electrolytic polishing, sand blasting, pickling |

Polishing precision | Inner surface Ra≤0.4μm, |

Normal Model And Main Technical Parameters

Parameters | Model | JTRPG—100 | JTRPG—300 | JTRPG—600 | JTRPG—1000 | JTRPG—2000 |

Effective volume:L | 100 | 300 | 600 | 600 | 2000 | |

Tank | Diameter:mm | Φ500 | Φ800 | Φ900 | Φ1100 | Φ1300 |

Height:mm | 500 | 700 | 900 | 1000 | 1500 | |

Agitator | Power:kW | 0.37 | 0.75 | 1.1 | 1.5 | 2.2 |

RPM:r/min | 36~53(Special open turbine impellers)/200(propeller)(Can adjust the design according to the customer's | |||||

The above-mentioned data is the standard, it can customize according to customer's requirements. | ||||||