T: +86-577-86867777

E: info@jhenten.com

E: info@jhenten.com

No.808 Haitong Road, Binhai Development Zone,Wenzhou Economic and Technological Development Zone,Zhejiang,China

TECHNICAL PARAMETERS

Standard Model | Filtration Area (m2 ) | Inner Diameter (mm) | Nominal Volume (m3 ) | Cylinder Height(mm) | Cake Height(mm) | Paddle Lifting Height(mm) | Stirring Motor Power(KW) | Equipment Net Weight (Kg) | Total Height of Equipment(mm) |

JTNB-400 | 0.12 | 400 | 0.05 | 450 | 100 | 120 | Manually Operated/0.75 | 250 | 1500 |

JTNB-500 | 0.19 | 500 | 0.15 | 650 | 140 | 160 | 2.2 | 1450 | 2600 |

JTNB-600 | 0.28 | 600 | 0.22 | 700 | 180 | 200 | 2.2 | 1650 | 2900 |

JTNB-800 | 0.5 | 800 | 0.53 | 900 | 200 | 220 | 3.0 | 2300 | 3300 |

JTNB-900 | 0.62 | 900 | 0.66 | 900 | 200 | 220 | 4.0 | 2800 | 3500 |

JTNB-1000 | 0.78 | 1000 | 0.93 | 1000 | 220 | 250 | 5.5 | 3600 | 3800 |

JTNB-1200 | 1.1 | 1200 | 1.3 | 1000 | 250 | 300 | 7.5 | 4700 | 3900 |

JTNB-1400 | 1.53 | 1400 | 2.0 | 1100 | 300 | 350 | 11 | 6400 | 4400 |

JTNB-1600 | 2.0 | 1600 | 2.7 | 1100 | 300 | 400 | 15 | 7400 | 4500 |

JTNB-1800 | 2.5 | 1800 | 3.8 | 1200 | 350 | 400 | 15 | 10500 | 4700 |

JTNB-2000 | 3.0 | 2000 | 4.8 | 1200 | 400 | 450 | 18.5 | 11500 | 5100 |

JTNB-2300 | 4.0 | 2300 | 6.8 | 1250 | 400 | 450 | 22 | 12600 | 5200 |

JTNB-2600 | 5.3 | 2600 | 9.1 | 1250 | 450 | 500 | 22 | 17200 | 5500 |

JTNB-2800 | 6 | 2800 | 10.8 | 1250 | 450 | 500 | 30 | 22000 | 5700 |

JTNB-3000 | 7 | 3000 | 14.4 | 1500 | 550 | 600 | 37 | 25000 | 5900 |

JTNB-3200 | 8 | 3200 | 16.6 | 1500 | 550 | 600 | 45 | 28000 | 6000 |

WORKING PRINCIPLE

◆Filling:

The vessel is filled with a slurry , generally fed from a reactor or crystallizing tank.

◆Filtration:

A liquid/solid be separated through the filter plate, Filtration(solvent) liquid be collected on mother liquid tank .

◆Washing:

Washing liquid are used to wash the product cake , The agitator is used the re-slurry the solid in a washing solvent.

◆Smoothing:

The agitator is used to smooth the wet cake in the filter dryer, to avoid the formation of cracks or preferential paths.

◆Drying and cooling:

Agitated vacuum drying consists in applying a vacuum on the vessel, while heating the walls and agitator using thermal circuits. This allows to reach the liquid boiling point and to dry the product.

◆Discharging:

The specially designed agitator pushes the product out from sterile discharge valve.

AGITATED NUTSCHE FILTER DRYER FLOW CHART

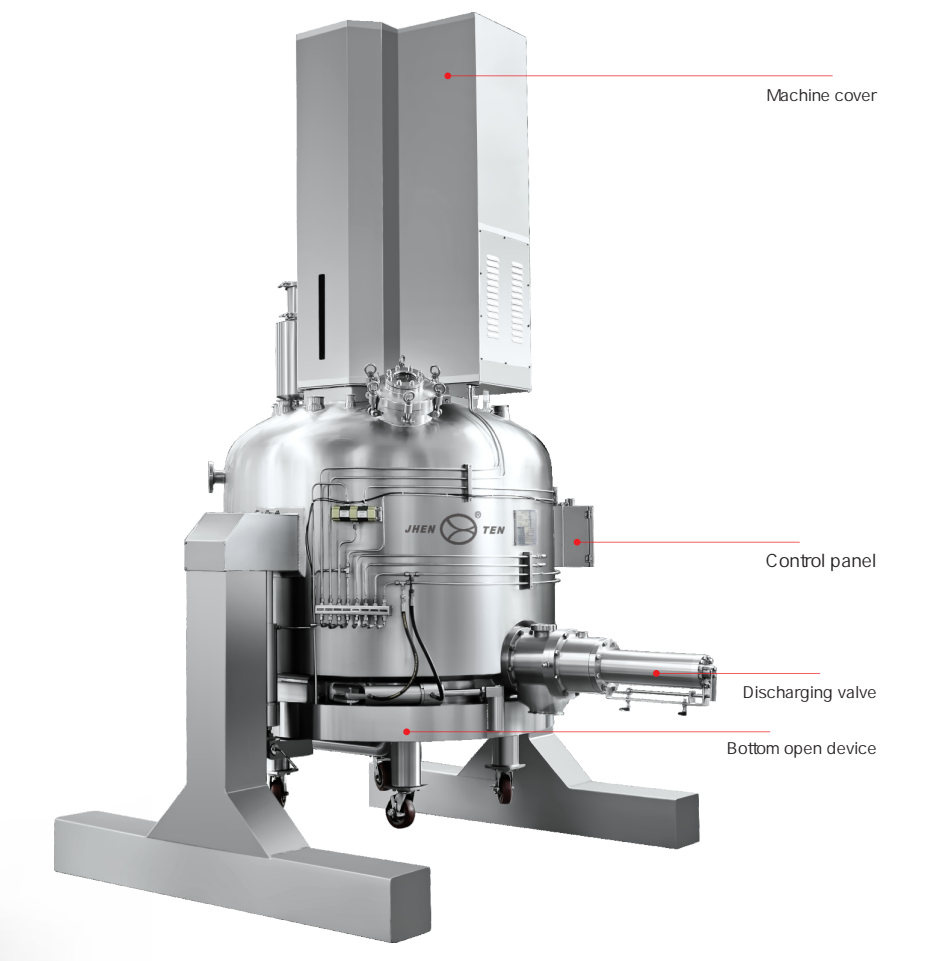

JTNB Agitated Nutsche Filter Dryer is a high-quality equipment designed for solid-liquid separation processes, by filtration under pressure and vacuum drying, can be use for the pharmaceutical, chemical, fine chemical and food industries.

Within the filtering applications, there are products which, due to their special hazardous or toxic characteristics, or prevent

cross-contamination, are more desirably treated in a hermetic way during their manufacturing process.

JTNB Nutsche Filter Dryers have been specially designed to guaranteeing the obtaining of pure substances which are free from polluting elements.Designed in accordance with the GMP standards, for all types of pharmaceutical and fine chemical applications. Our machines are validatable in sterile applications and we have special designs to install inside clean rooms.

FEATURES

◆Filtering surface from 0.07 up to 8 m2. Operation capacity from 20L up to 17 m3.

◆Operating pressure of 3 bar(g), Operation Temperatures up to 200℃.

◆Design according to Gb150l.

◆Hygienic design for pharmaceutical industrial, fully meet GMP and FDA requirements.

◆Direct contact parts of materials are made of 316L or 304, which are non-toxic and corrosion-resistant. Sealing material PTFE, FFKM or EPDM can be used.

◆Drive unit with stainless steel cover.

◆Heating/cooling of the body and/or agitator.

◆Bottom filter with automatic lifting and lowering, easy exchangeable filter plate.

◆Oil hydraulic bottom sealing system, automatic operate and safety.

◆Cake filtration, washing and purification.

◆Unloading of the cake by the sterile discharge valve.

OPTIONS

◆Internally mirror polished Ra ≤ 0.4 μm.

◆Internally electro polished (Ra≤ 0.2 μm).

◆Hastelloy(C276/C22), TA, Super duplex stainless steel and so on for option.

◆ASME VIII div.1-PED/CE/AD-2000/EN13445.

◆CIP/SIP systems.

◆Agitator with special sterile mechanical seal.

◆Aseptic sampling valve.

◆With condensation system , vacuum and heating unit.

◆Manual control and discharge;

◆GB/ATEX/C1D1 explosion proof execution with official certificate, UL/CSA list.

◆DQ, IQ and OQ protocols.

TYPICAL APPLICATIONS

◆FINE CHEMICALS and PHARMACEUTICAL:

Antibiotics, API, Biotechnology, Colorants, Crystals, Essences and flavors, Natural extracts, Peptides, Pharmacy synthesis, Vitamins..

◆CHEMICAL: Additives, Catalysts, Colorants, Metallic powders, Minerals, Pigments, Polymers.

◆FOOD: Additives, Animal extracts, Colorants, Flavors and aromas, Natural extracts, Vitamin complements.

TECHNICAL PARAMETERS

Standard Model | Filtration Area (m2 ) | Inner Diameter (mm) | Nominal Volume (m3 ) | Cylinder Height(mm) | Cake Height(mm) | Paddle Lifting Height(mm) | Stirring Motor Power(KW) | Equipment Net Weight (Kg) | Total Height of Equipment(mm) |

JTNB-400 | 0.12 | 400 | 0.05 | 450 | 100 | 120 | Manually Operated/0.75 | 250 | 1500 |

JTNB-500 | 0.19 | 500 | 0.15 | 650 | 140 | 160 | 2.2 | 1450 | 2600 |

JTNB-600 | 0.28 | 600 | 0.22 | 700 | 180 | 200 | 2.2 | 1650 | 2900 |

JTNB-800 | 0.5 | 800 | 0.53 | 900 | 200 | 220 | 3.0 | 2300 | 3300 |

JTNB-900 | 0.62 | 900 | 0.66 | 900 | 200 | 220 | 4.0 | 2800 | 3500 |

JTNB-1000 | 0.78 | 1000 | 0.93 | 1000 | 220 | 250 | 5.5 | 3600 | 3800 |

JTNB-1200 | 1.1 | 1200 | 1.3 | 1000 | 250 | 300 | 7.5 | 4700 | 3900 |

JTNB-1400 | 1.53 | 1400 | 2.0 | 1100 | 300 | 350 | 11 | 6400 | 4400 |

JTNB-1600 | 2.0 | 1600 | 2.7 | 1100 | 300 | 400 | 15 | 7400 | 4500 |

JTNB-1800 | 2.5 | 1800 | 3.8 | 1200 | 350 | 400 | 15 | 10500 | 4700 |

JTNB-2000 | 3.0 | 2000 | 4.8 | 1200 | 400 | 450 | 18.5 | 11500 | 5100 |

JTNB-2300 | 4.0 | 2300 | 6.8 | 1250 | 400 | 450 | 22 | 12600 | 5200 |

JTNB-2600 | 5.3 | 2600 | 9.1 | 1250 | 450 | 500 | 22 | 17200 | 5500 |

JTNB-2800 | 6 | 2800 | 10.8 | 1250 | 450 | 500 | 30 | 22000 | 5700 |

JTNB-3000 | 7 | 3000 | 14.4 | 1500 | 550 | 600 | 37 | 25000 | 5900 |

JTNB-3200 | 8 | 3200 | 16.6 | 1500 | 550 | 600 | 45 | 28000 | 6000 |

WORKING PRINCIPLE

◆Filling:

The vessel is filled with a slurry , generally fed from a reactor or crystallizing tank.

◆Filtration:

A liquid/solid be separated through the filter plate, Filtration(solvent) liquid be collected on mother liquid tank .

◆Washing:

Washing liquid are used to wash the product cake , The agitator is used the re-slurry the solid in a washing solvent.

◆Smoothing:

The agitator is used to smooth the wet cake in the filter dryer, to avoid the formation of cracks or preferential paths.

◆Drying and cooling:

Agitated vacuum drying consists in applying a vacuum on the vessel, while heating the walls and agitator using thermal circuits. This allows to reach the liquid boiling point and to dry the product.

◆Discharging:

The specially designed agitator pushes the product out from sterile discharge valve.

AGITATED NUTSCHE FILTER DRYER FLOW CHART

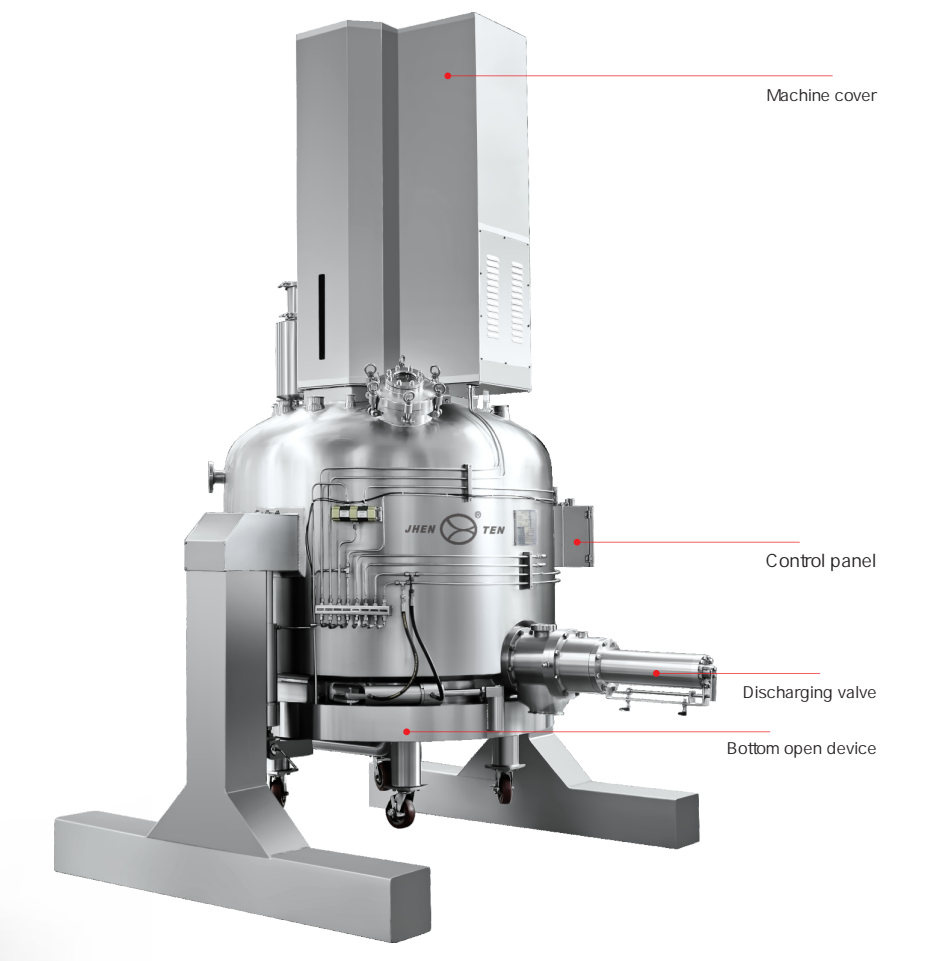

JTNB Agitated Nutsche Filter Dryer is a high-quality equipment designed for solid-liquid separation processes, by filtration under pressure and vacuum drying, can be use for the pharmaceutical, chemical, fine chemical and food industries.

Within the filtering applications, there are products which, due to their special hazardous or toxic characteristics, or prevent

cross-contamination, are more desirably treated in a hermetic way during their manufacturing process.

JTNB Nutsche Filter Dryers have been specially designed to guaranteeing the obtaining of pure substances which are free from polluting elements.Designed in accordance with the GMP standards, for all types of pharmaceutical and fine chemical applications. Our machines are validatable in sterile applications and we have special designs to install inside clean rooms.

FEATURES

◆Filtering surface from 0.07 up to 8 m2. Operation capacity from 20L up to 17 m3.

◆Operating pressure of 3 bar(g), Operation Temperatures up to 200℃.

◆Design according to Gb150l.

◆Hygienic design for pharmaceutical industrial, fully meet GMP and FDA requirements.

◆Direct contact parts of materials are made of 316L or 304, which are non-toxic and corrosion-resistant. Sealing material PTFE, FFKM or EPDM can be used.

◆Drive unit with stainless steel cover.

◆Heating/cooling of the body and/or agitator.

◆Bottom filter with automatic lifting and lowering, easy exchangeable filter plate.

◆Oil hydraulic bottom sealing system, automatic operate and safety.

◆Cake filtration, washing and purification.

◆Unloading of the cake by the sterile discharge valve.

OPTIONS

◆Internally mirror polished Ra ≤ 0.4 μm.

◆Internally electro polished (Ra≤ 0.2 μm).

◆Hastelloy(C276/C22), TA, Super duplex stainless steel and so on for option.

◆ASME VIII div.1-PED/CE/AD-2000/EN13445.

◆CIP/SIP systems.

◆Agitator with special sterile mechanical seal.

◆Aseptic sampling valve.

◆With condensation system , vacuum and heating unit.

◆Manual control and discharge;

◆GB/ATEX/C1D1 explosion proof execution with official certificate, UL/CSA list.

◆DQ, IQ and OQ protocols.

TYPICAL APPLICATIONS

◆FINE CHEMICALS and PHARMACEUTICAL:

Antibiotics, API, Biotechnology, Colorants, Crystals, Essences and flavors, Natural extracts, Peptides, Pharmacy synthesis, Vitamins..

◆CHEMICAL: Additives, Catalysts, Colorants, Metallic powders, Minerals, Pigments, Polymers.

◆FOOD: Additives, Animal extracts, Colorants, Flavors and aromas, Natural extracts, Vitamin complements.